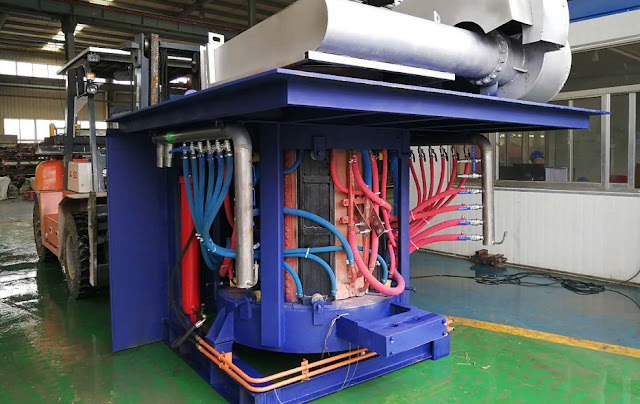

What is Medium Frequency Furnace?

Medium frequency furnace adopts 200-2500hz medium frequency power supply for induction heating and smelting heat preservation, mainly used for smelting carbon steel, alloy steel, seed steel, and also for smelting and temperature raising of copper, aluminum and other non-ferrous metals. The equipment is small in volume, light in weight, high in rate, low in power consumption, fast in melting and the temperature rising, easy to control furnace temperature and high in productivity

Working Principle of Medium Frequency Induction Water Heater

The power supply mode of the furnace is different from that of the power frequency electric boiler. The 380V power frequency AC power supply is input into the intermediate frequency power supply cabinet (the intermediate frequency power supply cabinet has over-voltage protection and over-current protection. If there is an over-voltage and over-current phenomenon, it will automatically shut down for alarm). In the intermediate frequency power supply cabinet, the power frequency AC power supply is rectified into single-phase DC power, and then it is converted into single-phase AC intermediate frequency voltage and current (in single-phase AC Frequency voltage and current are safety), the single-phase AC medium frequency voltage and current are input into the heater to generate induction electricity and conduct induction heating on the water in the boiler. Therefore, the water and electricity are separated in the heating process of the boiler, which is reliable.

The boiler is also equipped with the following protection devices.

1. Equipped with a temperature controller and water control instrument, it can automatically adjust the temperature and make up the water, set the water supply temperature and return water temperature according to the user's needs. When the water supply temperature is higher than the set temperature, it will stop automatically, and when the return water temperature is lower than the set temperature, it will start automatically.

2. It is equipped with liquid crystal digital display, which can accurately and intuitively display the water supply temperature and return water temperature; the water level in the furnace can be displayed on the water level gauge, and the operator can clearly grasp the operation of the boiler.

3. The alarm of water control and sensor temperature regulation can be switched into the automatic protection system. In case of failure, the corresponding indicator light will flash and stop automatically.

Free send inquiry to stella@hanrm.com if any needs.

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com

More News You May Interesting:

What is Induction Furnace?

How does a Blast Furnace Work?

Significance of Reheating Furnace Technology in Rolling Reheating Furnace

Why Use Coke for Blast Furnace Ironmaking does not Use Coal Directly?

How to Improve the Thermal Efficiency of the Reheating Furnaces?

What is the Reheating Furnace Temperature System?

Advantages of Walking Beam Reheating Furnace

Walking Beam Reheating Furnace

The Development Trends and Advantages of Electric Arc Furnaces

The Advantage of Induction Furnace ( Medium Frequency Furnace)

On the Advantage and Disadvantage of Electric Arc Furnace and Induction Furnace

评论

发表评论