Электродуговая печь

Энергосберегающий и экологически чистый процесс производства стали и оборудование для дуговых электропечей

ВОСПРОИЗВЕСТИ ВИДЕО

Индукционная печь

Решения для оснащения высокопроизводительных индукционных сталеплавильных печей

ВОСПРОИЗВЕСТИ ВИДЕО

Машина непрерывного литья заготовок

Большой опыт в проектировании, производстве, монтаже и вводе в эксплуатацию машины непрерывного литья заготовок

ВОСПРОИЗВЕСТИ ВИДЕО

Previous slide

Next slide

Продукт

Промышленное решение

01.

Машина непрерывного литья заготовок МНЛЗ Проектное решение под ключ

Всесторонние решения для технологий и оборудования машин непрерывного литья заготовок

Узнать сейчас

02.

Сталеплавильное производство в электродуговой печи

Благодаря оптимизированному процессу выплавки стали, высокопроизводительному оборудованию, сильной технической подготовке и богатому практическому опыту

Узнать сейчас

03.

Проектное решение "под ключ" для индукционной печи

Hani Metallurgy - высокотехнологичное предприятие, специализирующееся на производстве оборудования для индукционного нагрева, объединяющее производство, исследования и разработки

Узнать сейчас

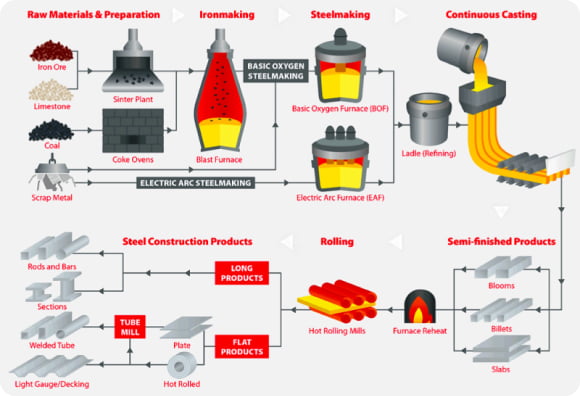

Технологическая схема производства

Длительный процесс

Обогащение → Спекание → Доменная печь → Жидкий чугун → Предварительная обработка жидкого чугуна → Кислородно-конвертерная печь → Первичный расплав стали → Внешнее рафинирование → Установка непрерывного литья заготовок → Заготовка для непрерывного литья заготовок

Короткий процесс

Стальной лом → Электродуговая печь → Первичный расплав стали → Внешнее рафинирование → Установка непрерывного литья заготовок → Заготовка для непрерывного литья заготовок

Материалы для производства стали в электродуговых печах

Материалы для производства стали в электродуговых печах Что такое электродуговая печь? Электродуговая печь - это электропечь, которая плавит руды и металлы при высоких температурах, создаваемых электродными дугами. Она более гибкая, чем другие сталеплавильные печи, позволяет эффективно удалять серу, фосфор и другие примеси, температуру печи легко

continue reading

Технология водородного рафинирования расплавленной стали

Жидкая сталь является важным металлическим материалом, широко применяемым в различных областях. Однако

continue reading

Технология плавки в руднотермической печи мощностью 6300 кВА

Технология плавки в руднотермической печи мощностью 6300 кВА - это эффективная и

continue reading

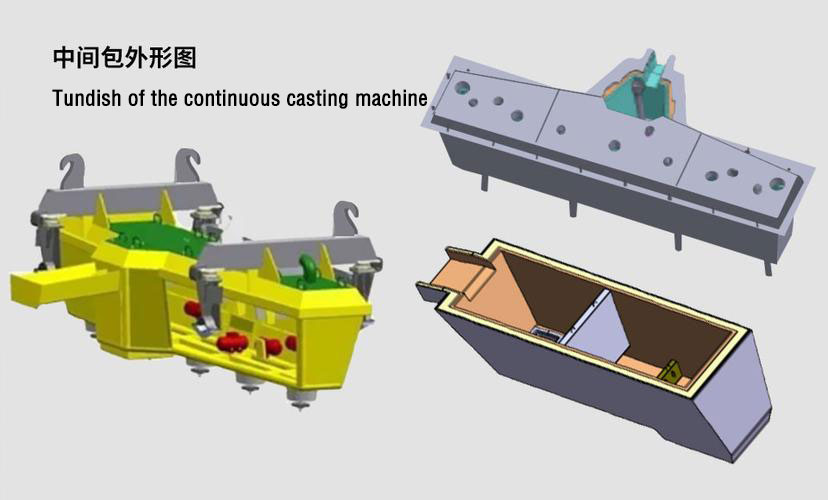

Промежуточный ковш машины непрерывного литья заготовок

Промежуточный ковш машины непрерывного литья заготовок является важным компонентом производственного процесса машины

continue reading