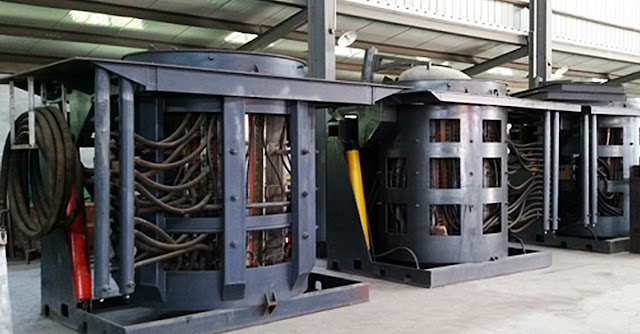

Electric Arc Furnace VS Induction Furnace Steelmaking

Comparison of advantages and disadvantages of electric arc furnace and induction furnace steelmaking

1. The induction furnace heats up quickly and has high thermal efficiency. The heat is generated inside the charge (steel liquid), so the heating is fast. In the arc furnace, the heat of the arc after the material is cleared must be transferred to the molten steel through the slag, which is indirect heating. Thermal efficiency is poor. The furnace is in the shape of a basin, and a large part of the heat of the arc is lost through the furnace cover and the furnace wall.

2. The oxidative burning loss of elements in induction furnace steelmaking is less. Because there is no ultra-high temperature action of the arc in the induction furnace steelmaking, the burning rate of the elements in the steel is low.

3. In the induction furnace steelmaking, the composition and temperature of the molten steel are relatively uniform. Because it is the electromagnetic force, the inductor and the molten steel repel each other, so that the molten steel in the center part of the crucible rises, and the molten steel in the edge portion of the crucible Dropped, resulting in the phenomenon of molten steel circulation. This electromagnetic stirring action promotes the uniformity of the chemical composition and temperature of the molten steel in the molten pool and facilitates the floating of non-metallic inclusions in the molten steel.

4. The slag in induction furnace steelmaking has poor ability to participate in the metallurgical reaction. In electric arc furnace steelmaking, the temperature of the slag is higher than that of the molten steel, and the slag has a strong ability to participate in metallurgical reactions. In the induction electric furnace, the slag is heated by the molten steel, and the temperature is low, so the ability to participate in the metallurgical reaction is weak. Therefore, in the induction electric furnace steelmaking, the effects of the metallurgical processes such as desulfurization, dephosphorization and diffusion deoxidation are worse than those of the electric arc furnace.

5. The charge (scraper) for induction furnace steelmaking is highly demanding. Due to the weak metallurgical reaction ability of induction electric furnace steelmaking, it is more important than remelting, so it needs better furnace material (good material, less rust, and oil), and the block shape can not be larger.

6. Induction furnace steelmaking is more in line with environmental protection requirements, while electric arc furnace steelmaking produces a large amount of exhaust gas, waste residue, and noise, and has high energy consumption.

As a result, some larger foundries have also eliminated the electric arc furnace and changed to an intermediate frequency furnace. With the emergence of a large number of high-quality scrap steel on the market, such as a scrap of cold-rolled stampings and the trimming of marine steel plates, small and medium-sized cast steel mills have eliminated the electric arc furnace and changed to an intermediate frequency furnace.

Free send inquiry to stella@hanrm.com if any needs of electric arc furnace or induction furnace.

Whatsapp/Wechat:+8615877652925

Website: https://www.hanrm.com

评论

发表评论